Towards a Compliant Cobot for Safe Human-Robot Collaboration in Harsh Environments: HMU’s Elongating and Bending Soft Pneumatic Actuators in the ARISE Project

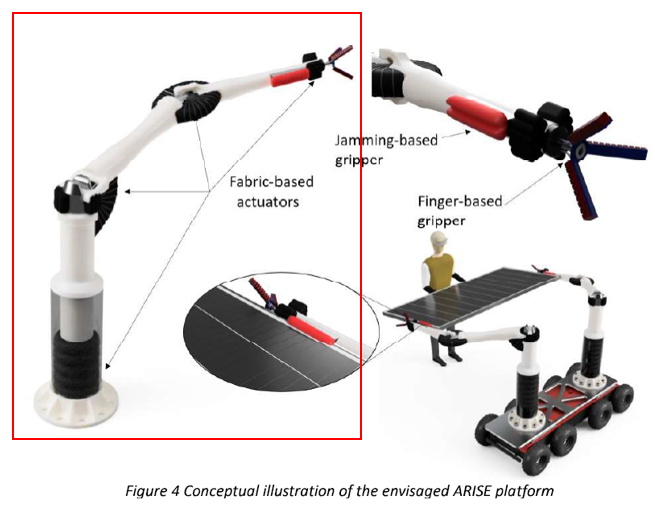

As part of the Horizon Europe-funded ARISE project, HMU is developing innovative designs of individual and group soft fabric actuators, able to exert forces or torques in wide ranges or rotations. These actuators will drive a compliant robotic manipulator to perform both heavy- duty and delicate tasks in challenging environments such as solar farms and hydroponic facilities, while ensuring safe collaboration with human workers. This technology is designed to support human workers in demanding conditions, improving efficiency and safety in the renewable energy and agricultural sectors.

Elongating and bending soft pneumatic actuators

The actuation of the soft fabric actuators used in this project relies on pneumatic pressurisation of high-strength fabrics and polymer films, which form flexible geometrical structures capable of providing both variable stiffness and compliance. To execute all tasks, the robotic manipulator must perform both axial and rotational movements—enabled by elongating and bending actuators, respectively. These actuators are nested in rigid housing joints, allowing for seamless and controlled motion. According to the project’s final use cases, the robotic manipulator aims to perform specific tasks in solar farm environments (such as solar panel installation and repair) and hydroponic environments (such as lettuce transplanting and harvesting). The proposed pneumatic actuators feature ingress protection, enabling them to operate effectively without performance degradation in dusty (solar farms) and high-humidity (hydroponic farms) environments.

Safe and easy human-robot collaboration

The robotic manipulator must be designed to ensure safe collaboration with human workers. To this end, the soft pneumatic actuators can perform heavy-duty tasks while remaining compliant enough to avoid unintended or hazardous interactions. By adjusting the internal pressure, the actuators can vary their stiffness, enabling the manipulator to apply the appropriate level of force for each task. Furthermore, the motion of the end effector and the manipulator is designed to mimic typical human velocities and accelerations. This ensures that the robot operates in a manner that feels natural and non-threatening, always prioritising human safety.

Towards a smooth and accurate manipulator

As the ARISE project progresses, actuator pressure and position will be precisely controlled using integrated sensors and advanced control algorithms. This will enable smooth and accurate movement of both the robotic manipulator and its end-effector. By integrating complex mechanical, electronics, and pneumatic systems, the envisioned robotic manipulator will enhance automation in the solar energy and agriculture sectors.